What is an FMECA?

The FMECA (Analysis of Failure Modes, Effects and their Criticality), is a methodology to identify and analyze all the potential failure modes of the different parts of a system, the effects that these failures may have on the system, how to avoid failures and / or mitigate their effects on the system.

In other words and simplifying, the FMECA is a technique to identify, prioritize and eliminate possible system failures (at the design or process level). The FMECA basically differ from FMECA Design and FMECA Process : the first refers to the product or system itself, the second focuses on the problems arising from how the equipment is manufactured, maintained or operated.

Initially the FMECA was called FMEA. The C is a new parameter that is being used more and more, which indicates the criticality or severity of the various effects of the failures, being able to prioritize their importance.

To that is an FMECA used ?

Have

an objective criterion for selecting design alternatives during

the initial phases of a product or system development

- Have a method to consider all possible failure modes as well as their effects

- List possible failures and identify the severity of their effects

- Develop criteria to execute a robust and effective test plan to detect problems

- Accumulate knowledge for future developments and design changes

- Provide a basis for maintenance planning

- Provide a basis for RAMS reliability analysis

How is an FMECA carried out ? Then we describe the 4 essential steps of an FMECA process

Step 1: Prepare the AMFEC

Initially, the system to be analyzed must be correctly defined, keeping in mind whichwhichare the limits of the system, that is, which parts should be included and which ones are excluded from the FMECA analysis , taking into account that the interfaces of the limit of the equipment to be analyzed must also be included in the analysis. It is also important to be clear about the operating and environmental conditions to consider. Temperature or mechanical stress, for example, play a fundamental role in equipment failure modes.

On the other hand, it is important to have all the necessary information about the system to be analyzed, including schematics, block diagrams, list of components, interface information, functional descriptions, etc. An FMECA is carried out understanding what the system does because it should be seen how failures affect the correct operation of the system. Therefore, understanding what correct operation means is necessary. Finally, if available, we always recommend using the return on experience ( REX ) in similar processes and / or similar products from the past. You can also recommend consulting the suppliers of the components that we are going to analyze our intention to carry out an FMECA with the intention that they send us all the information about their components in this regard.

Step 2: Analysis of the system structure

Carrying out an FMECA can be seen as something impossible to manage due to its complexity and laboriousness. Thus, the system must be divided into manageable units or components , generally in a way that makes sense from the point of view of the system architecture developed for product development. From here, make small FMECAs of each block obtaining totalized failure modes of each block to see how these affect some components with respect to others. Obviously, whenever possible, the analysis should be simplified, which in most cases implies analyzing the "higher the better", the failure modes of the components . It tends to make it difficult the more we go down to atomic analysis (to the minimum component) the system, although sometimes (on all the first few times when components are not reused) , it is absolutely necessary. As identified quickly, using an architecture blocks reused and where the FMECA is done, it will represent an important advantage in time and cost.

Step 3: Failure analysis and preparation of AMFEC tables

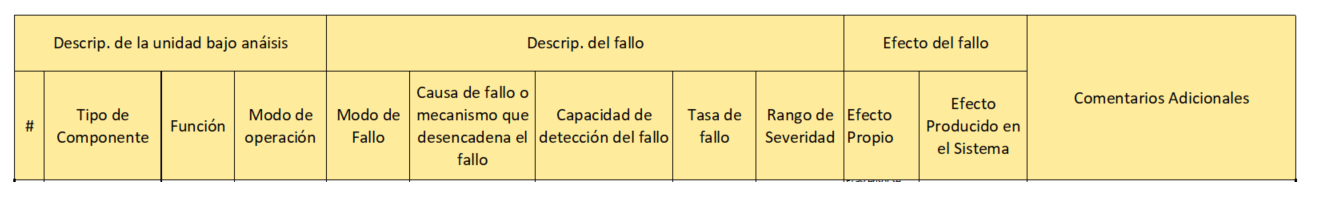

For the first FMECA that are carried out, the company must decide thatthattemplate to use. The template is usually summarized in a few columns in a spreadsheet or using a specific tool for FMECA development . Leedeo recommends the following template to his clients as a basis for creating his own as he evolves and gains experience in these types of activities.

For each element of the system the analysis must consider all the functionalities of the elements in all their operating modes , and analyze whether any failure of the element may result in an unacceptable effect of the system.

In RAMS systems where safety is

a design factor, we usually recommend expanding in the "Effect Produced in

the System", a new row with the following columns to check : effect

on safety, effect on reliability .

Step 4: Review of the executed FMECA and corrective actions

Once all the FMECA analysis has been carried out , it is customary to carry out a pooling session , where it is recommended that all components of the project team participate: the project manager, the design engineer and the process engineer, the RAMS engineer , the engineer responsible for maintenance, etc.

The objective of the task force is to study the FMECA worksheets to decide if the system is acceptable as it is, to identify feasible improvements to the system and those that will finally be implemented with an order of priority . Without being strict, we recommend that you normally use this " check-list " to find solutions to the problems detected : design changes, changes in procedures or in the way of WhatWhat The equipment must be used, component changes as different failure modes, use of systems or devices to warn of an event that generates a failure, mitigate the effects with some incorporation into the design.

Conclution

A FMEA are typical and necessary activities of an analysis process RAMS . For a system or product under control from the point of risks, it is essential to know in which way fails , can predict and mitigate unwanted event beforehand . At Leedeo Engineering we have extensive experience in the development of these RAMS activities. Do not hesitate to contact us >> .

At Leedeo Engineering , we are specialists in the development of Railway RAMS projects, providing support at any level required for RAM and Safety tasks, and both at the infrastructure level or on-board equipment.

Are you interested in our articles about RAMS engineering and Technology?

Sign up for our newsletter and we will keep you informed of the publication of new articles.